Visual Defect Checker

Detect Visual Defects Early—Before They Become Costly

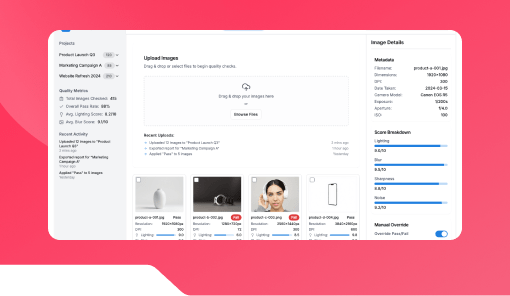

Automated visual defect detection tool

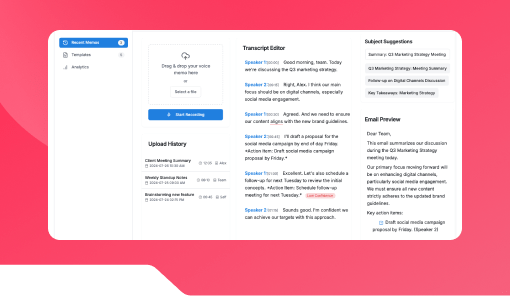

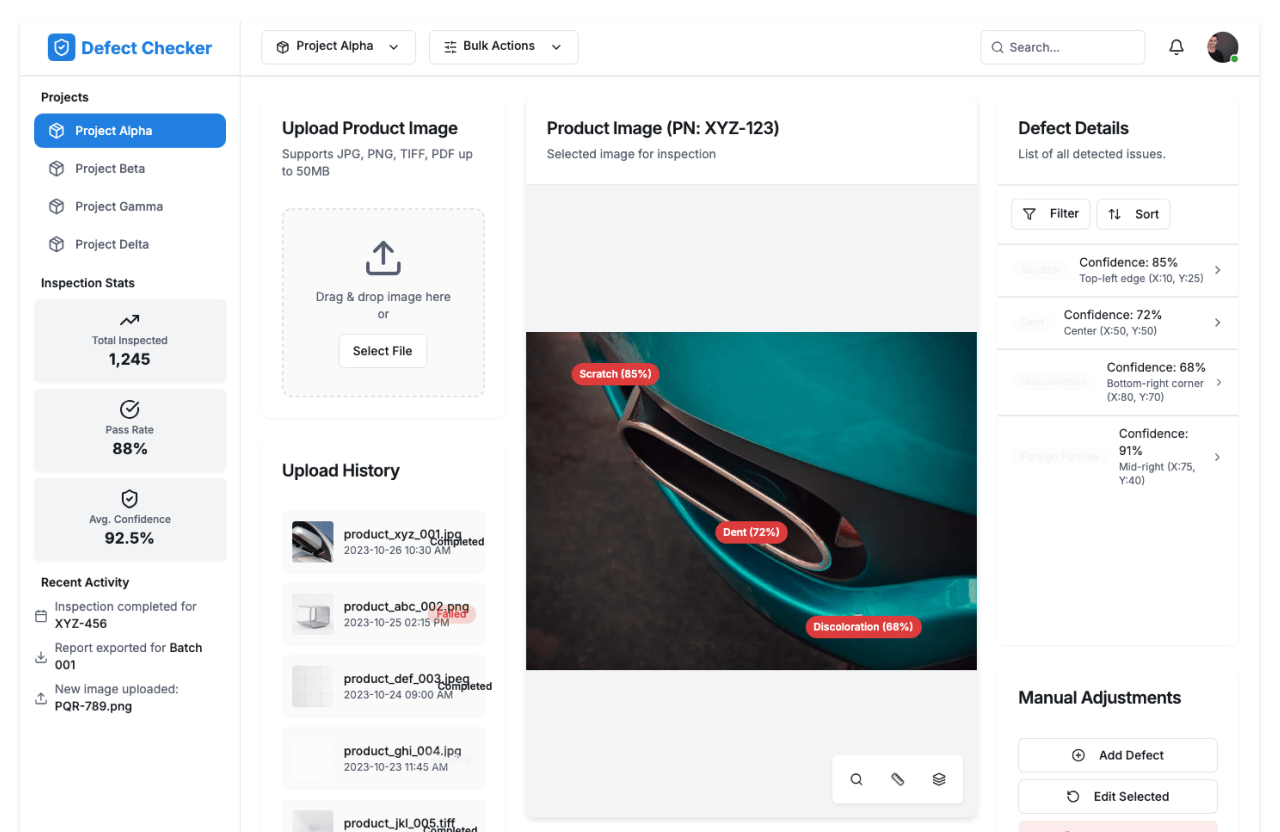

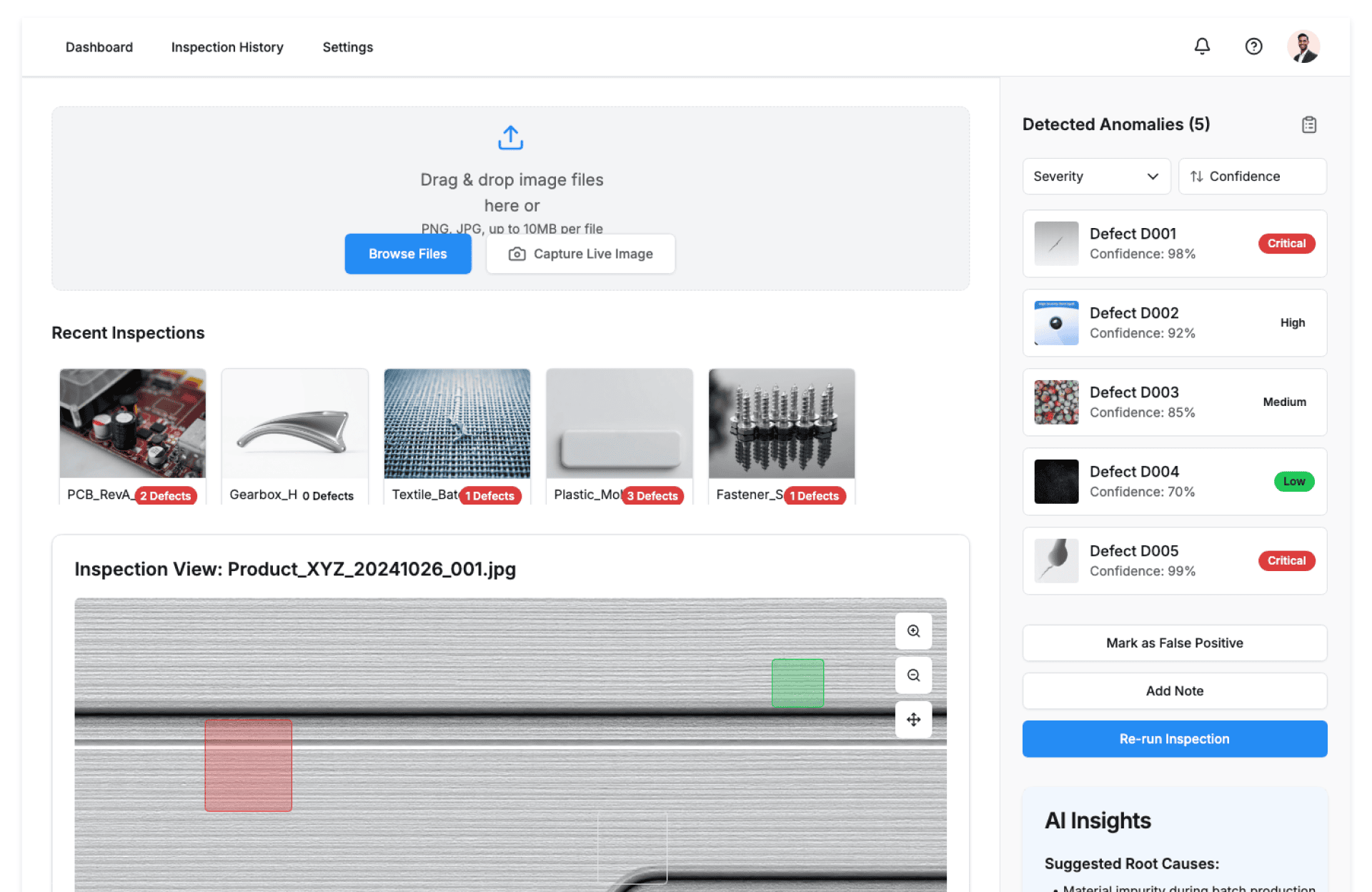

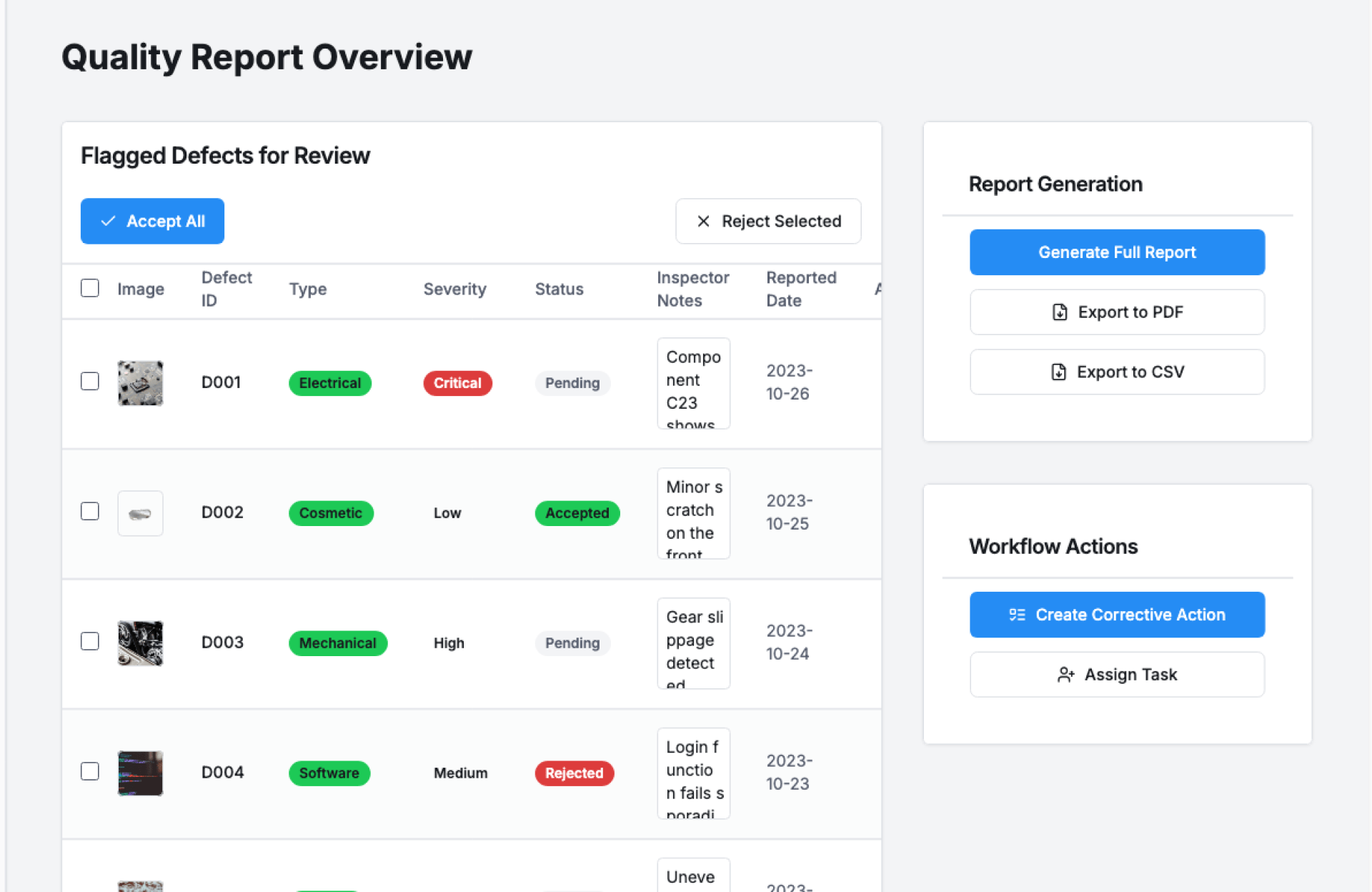

See Visual Defect Checker In Action

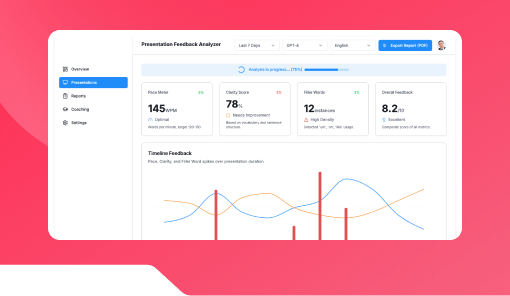

The Visual Defect Checker by Kriatix automatically inspects images or video frames to identify visual defects such as scratches, cracks, misalignments, discoloration, or missing components. It reduces manual inspection effort and improves quality consistency across products and processes.

Built for speed and accuracy, it brings reliable visual inspection to scale.

🔹 Start Free Trial

🔹 Book a Demo

🔹 Request Pricing

What Is the Visual Defect Checker?

The Visual Defect Checker is a ready-to-use inspection tool that analyzes visual inputs to detect anomalies and defects against defined quality standards. It flags defective items instantly and provides clear visual markers—helping teams take corrective action faster.

It works across manufacturing, packaging, retail, logistics, and quality assurance workflows.

Who Is It For?

| Role | How They Benefit |

|---|---|

| Quality Assurance Teams | Reduce manual inspection workload |

| Manufacturing Ops | Catch defects early in the process |

| Product Managers | Maintain consistent quality standards |

| Operations Leaders | Reduce rework and returns |

| Founders & CXOs | Improve quality without scaling costs |

Key Features

- Automated visual defect detection

- Image and video-based inspection support

- Customizable defect rules and thresholds

- Visual highlighting of detected defects

- Batch inspection for high-volume inputs

- Inspection logs and defect history

- Role-based access and controls

Benefits

- Improve defect detection accuracy

- Reduce human error in inspections

- Catch issues earlier in the workflow

- Lower rework, scrap, and return costs

- Maintain consistent quality standards

- Scale inspection without extra manpower

How It Works

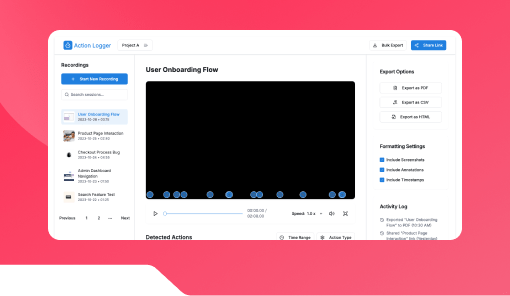

- Capture Visual Input – Upload images or video frames

- Analyze Visuals – Compare against quality rules

- Detect Defects – Flag anomalies and issues

- Review Results – Inspect highlighted defect areas

- Act & Record – Take corrective action and log outcomes

Add-ons & Integrations

- Product Image Labeler

- Image-to-Text Extractor

- Quality Audit Checklist Dashboard

- Manufacturing Execution Systems

- API-based inspection workflows

Deployment & Access

- Web-based inspection dashboard

- Cloud-hosted or on-premise deployment

- Secure image and inspection data handling

- Role-based access and permissions

What Our Partners Are Saying

Frequently Asked Questions

What types of defects can be detected?

Scratches, cracks, misalignments, discoloration, and missing parts.

Can defect rules be customized per product?

Yes. Quality thresholds and defect criteria are configurable.

Does it support bulk inspections?

Yes. High-volume batch processing is supported.

Can results be reviewed visually?

Yes. Defect areas are clearly highlighted.

Is inspection data stored securely?

Yes. Enterprise-grade security and access controls apply.

Ready to Automate Smarter with Kriatix?

Build next-gen, AI-powered apps and workflows—faster, smarter, and tailored to your industry.

Get Started